Shop tour: Ruckus Composites carbor fiber repair

Originally posted on August 20, 2014 at 13:52 pm

Apart from wheel sizes and the number of gears involved, the biggest trend in the mountain bike industry in the last decade has been carbon fiber. You can get carbon anything these days: frames, rims, handlebars, brake levers, stems, seatposts, cranksets, chains… ok, maybe not chains, but the Gates Carbon Belt Drive is pretty close.

And while it makes for an excellent structural material, like anything you throw down a mountain as fast as you can, things can break. When you drop three months salary on a new mountain bike (what else would you spend that kind of money on?) it can be a bitter pill to swallow when you realize even the strongest carbon fiber has its limits. That’s where Ruckus Composites comes in.

With more than a decade of carbon fiber repair experience, Shawn Small and his team have made repairing or reviving carbon frames an art form, with exacting OE-style refinishes and modifications to carbon frames.

Portland, Oregon, is widely considered Bike Capital USA with a massive commuting, cyclocross and road racing scene. While it doesn’t have much of a mountain bike scene in the city itself, there is an endless variety of amazing terrain throughout the state and the Northwest as a whole. Like so many hidden gems, the Ruckus HQ occupies a nondescript brick building in an industrial part of town. A few times an hour the railroad tracks outside the doors rumble to life and a passing train rocks the building with its diesels and decibels.

It’s not plastic

Constructing frames from carbon fiber might be a complicated technique, but repairing them turns out to be simpler than most people would expect—at least to the untrained eye. “Carbon fiber has a lot of positive attributes,” Small said. “The primary one being is how light it is. It is also incredibly tailorable for any sort of situation. I mean they are building prototype tank shells and airplanes out of it, two very different situations. The repairability is also great, generally only a localized region has to be repaired which helps keep the overall costs down.”

A dozen or two bikes are in the shop at any given time, and Small says even he is surprised by the demand for his services. There are a few things they won’t do, however, such as fix your broken hockey sticks, handlebars or kayak paddle. The small, quick and dirty repairs just aren’t worth their time, he said. What is more interesting and fun are the kinds of no-expense-spared projects they get from time to time, like a custom, one-off bike travel case for a client.

Healing powers

The first step in the repair process is an online form submitted by the customer with a basic outline of what happened and what the damage is, ideally with photos attached. This allows Ruckus to make an estimate about the extent of the repair needed and the cost involved.

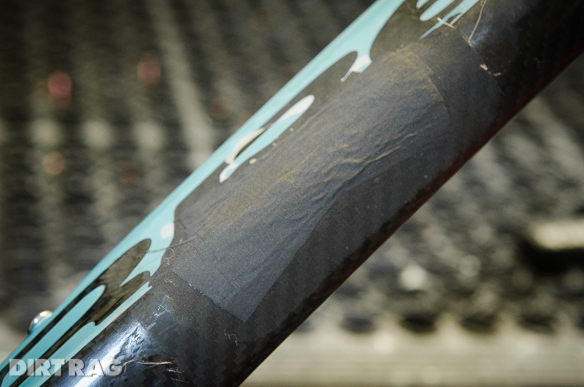

“Our most common repair is the seat stay. Usually impact from some sort of accident or derailleur falling off,” Small said. “Also it is the lightest tube on the bike at this point, so it doesn’t exactly take damage well.” To fix that seat stay, the area is cleaned and sanded to reveal the extent of the damage.

Ruckus will then consult with the client on their budget, their expectations and how they want to proceed. Ruckus uses several different types of carbon to match the original frame construction as closely as possible.

One is a unidirectional ribbon that is used for small repairs.

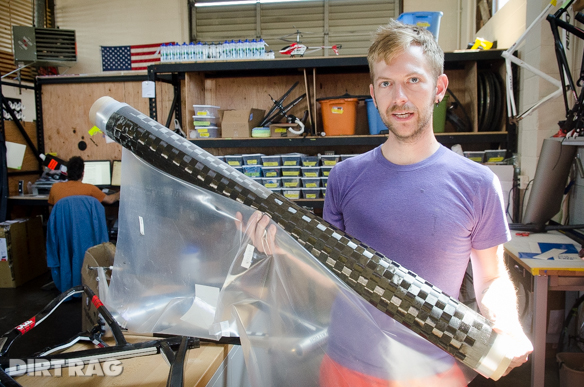

The woven carbon is much stronger, Small says, because the contrasting grains of fibers dissipate impacts and keep cracks from spreading. It is the same Swedish carbon with a broad, checkerboard weave pattern that you can see on some 2015 Felt bikes.

Since dropouts are often a source of damage, Ruckus sources and stocks its own solid dropouts that can be affixed to most frames and are usually stronger than the stock pieces.

Without giving away any of their secret sauce, Ruckus impregnates the carbon in resin before applying it to the damaged area and then bakes it in a low-heat oven for up to 12 hours.

The long, low heat curing process allows the resin to set without disrupting the existing carbon or even paint.

The frames are then painted to exacting OE specs or given a full custom treatment. Ruckus can produce its own graphics to match or update anything you’d like. All repairs are made to ASME and ASTM standards so you can trust that it is safe and sturdy.

Another fun option is refinishing bikes to give them a new lease on life. This customer wanted to refresh his Trek frame as a singlespeed with gloss-on-matte logos and no derailleur guides.

Making things easier

While most folks who damage their carbon frame will first inquire about a warranty through their local bike shop, they are often out of luck. To simplify the process of getting them back on the trail (or road), Ruckus has created a Trusted Carbon Fiber Service Network with bike shops to expedite the process.

Ruckus will supply participating shops with padded, branded boxes for the shop to easily send the frame to Portland. Shops make money in the process by removing all components from the customer’s bike as well as rebuilding it, and they can keep the customer happy by providing a trusted repair option instead of saying “Sorry, you’re out of luck.” Customers will also be directed to the closest participating shop through the Ruckus website.

Cracking or breaking a carbon frame is certainly not a pleasant experience—for your ride or your wallet—but knowing there is a viable repair service should put to rest a lot of customers’ fears of buying a carbon fiber bike.